Aluminum Fence Panels: Elevate Your Curb Appeal & Security

Introduction to Aluminum Fence Panels

Imagine transforming your property’s boundaries with a solution that combines elegance, strength, and low maintenance. Aluminum fence panels are increasingly becoming the go-to choice for homeowners and businesses alike, thanks to their remarkable versatility and enduring appeal. But why have these panels gained such popularity, and what makes them a standout option for both residential and commercial settings?

To start with, aluminum fence panels are celebrated for their durability and resistance to the elements. Unlike traditional wood fences that can warp or rot over time, aluminum stands strong against weather extremes without succumbing to rust or decay. This resilience makes them an ideal choice for those seeking a long-term fencing solution.

Moreover, the aesthetic appeal of aluminum fencing is undeniable. Available in a variety of styles and finishes, these panels can complement any architectural design—from the sleek lines of modern homes to more traditional settings. Whether you prefer the minimalist look of clean lines or the ornate elegance of decorative accents, aluminum fence panels offer a range of options that enhance curb appeal.

Another key advantage is the ease of maintenance. Aluminum fences require minimal upkeep compared to wood or wrought iron. A simple rinse with a garden hose is often enough to keep them looking pristine, freeing you from the burdens of regular painting or staining.

In commercial applications, aluminum fence panels provide a robust and secure perimeter without compromising on style. Their lightweight nature allows for easier installation, reducing labor costs and time. As businesses and homeowners continue to seek out sustainable and visually appealing fencing solutions, aluminum panels remain a top contender, offering a perfect blend of functionality and design.

Getting Familiar with Basic Aluminum Fence Panels

When considering a fencing solution that combines durability with aesthetic appeal, aluminum fencing panels emerge as a top choice. But what makes these panels so special? Let's delve into their fundamental features and why they are favored by so many homeowners and businesses.

Corrosion Resistance and Durability

Aluminum fencing panels are renowned for their corrosion resistance. Unlike iron or steel, aluminum does not rust, making it an excellent option for properties exposed to harsh weather conditions. This resistance ensures that your fence maintains its structural integrity and appearance over time, reducing the need for frequent repairs or replacements.

Lightweight and Easy Installation

One of the standout features of fence aluminum panels is their lightweight nature. This characteristic not only makes them easier to transport but also simplifies the installation process. Whether you're a DIY enthusiast or hiring professionals, the ease of handling aluminum panels can significantly cut down on labor costs and installation time.

Versatility in Sizes and Applications

Aluminum fencing panels are available in various heights, commonly ranging from 4 ft to 8 ft, catering to different needs and preferences. For residential settings, 4 ft panels are often used for garden boundaries, while 6 ft and 8 ft panels provide enhanced security and privacy for backyards. This versatility allows homeowners to choose a height that best suits their property's layout and security requirements.

In summary, the combination of corrosion resistance, lightweight properties, and ease of installation makes aluminum fencing panels an attractive option for both residential and commercial applications. As you explore your fencing options, consider how these panels can meet your needs for durability and style, ensuring a long-lasting investment for your property.

Choosing Dimensions and Styles for Your Property

When planning to install aluminum fence panels, selecting the right dimensions and styles is crucial to achieving both functional and aesthetic goals. The dimensions of your fence will largely depend on your property's size, layout, and specific security needs. Let’s explore how to make the best choices for your home or business.

Determining the Right Dimensions

Begin by assessing your property's layout and the primary purpose of your fence. For instance, if you aim to enclose a large backyard, opting for 8 ft aluminum fence panels can offer enhanced privacy and security. These taller panels are particularly effective in deterring intruders and keeping pets safely within your property.

Conversely, if your goal is to define a garden area or front yard, shorter panels, such as those around 4 ft or 6 ft, might suffice. They provide a clear boundary without obstructing views, allowing you to maintain an open and welcoming appearance.

Exploring Style Options

Aluminum fence panels come in a variety of styles, each contributing differently to your property's curb appeal and functionality. Here are some popular options:

- Picket-Top: This classic style offers a traditional look, often associated with suburban homes. It provides a friendly boundary while maintaining visibility.

- Flat-Top: Ideal for a modern aesthetic, flat-top panels offer a sleek and clean appearance, suitable for contemporary homes and commercial properties.

- Spear-Top: Featuring pointed finials, spear-top designs add an element of security and elegance. They are often used for properties requiring a more formidable barrier.

Each style can significantly impact your property's overall look and should be chosen based on the architectural style of your home and personal preferences.

Considering Regulations and Guidelines

Before finalizing your fence dimensions and style, it's essential to check local regulations and Homeowners Association (HOA) guidelines. Many areas have specific rules regarding fence height, style, and placement to ensure neighborhood uniformity and safety standards.

Consulting with local authorities or your HOA can prevent potential conflicts and ensure your new fence complies with all necessary regulations. This step is vital to avoid costly modifications or fines after installation.

In conclusion, choosing the right dimensions and styles for aluminum fence panels involves careful consideration of your property's needs and local regulations. By balancing functional requirements with aesthetic preferences, you can enhance both the security and appeal of your property.

Exploring Privacy and Ornamental Enhancements

When it comes to enhancing both privacy and aesthetic appeal, aluminum fence panels offer a variety of solutions that cater to different homeowner needs. Let's delve into how aluminum privacy fence panels and decorative aluminum fence panels can transform your property.

Aluminum Privacy Fence Panels

For homeowners who prioritize seclusion, aluminum privacy fence panels are an excellent choice. These panels are designed to provide a solid barrier, effectively blocking views from the outside while maintaining a sleek and modern appearance. Available in styles like shadowbox and board on board, these panels offer varying levels of visibility and light penetration. For instance, the shadowbox design allows light to filter through at certain angles, creating a balance between privacy and openness. On the other hand, the board on board option completely obstructs the line of sight, offering maximum privacy.

These privacy solutions are not only functional but also come in a range of heights—typically 4', 6', and 8'—to suit different privacy needs and local zoning regulations. Whether you're looking to create a private oasis in your backyard or secure a pool area, aluminum privacy fence panels provide a durable and stylish solution.

Decorative Aluminum Fence Panels

If enhancing the visual appeal of your property is a priority, consider incorporating decorative aluminum fence panels. These panels come in various ornamental styles that can complement any architectural design, from traditional to contemporary. Features such as intricate finials, scrolls, and unique post caps add a touch of elegance and sophistication, making your fence a standout feature in your landscape.

Beyond aesthetics, decorative panels also serve functional purposes. They can demarcate boundaries and provide a level of security without compromising on style. The choice of decorative elements can reflect personal taste and enhance the overall character of your property.

Balancing Design with Functionality

When selecting between privacy and decorative options, it's crucial to balance design appeal with functionality. Consider how each type of panel aligns with your property's needs. For instance, if your primary concern is privacy, opt for solid panels that offer full coverage. However, if you're looking to boost curb appeal while maintaining some level of transparency, decorative panels with ornate designs might be the way to go.

Ultimately, the decision should reflect both your aesthetic preferences and practical requirements. By choosing the right combination of aluminum fence panels, you can enhance your property's privacy and charm, creating a welcoming and secure environment.

Considering Color Options for Residential Appeal

When it comes to choosing aluminum fence panels, color plays a pivotal role in defining the aesthetic appeal of your property. Among the myriad of options available, black aluminum fence panels and white aluminum fence panels are particularly popular for their versatility and timeless elegance.

Black Aluminum Fence Panels

Black is a classic choice that exudes sophistication and seamlessly blends with various architectural styles. Whether your home is modern or traditional, black panels provide a striking contrast against lush greenery and vibrant landscapes, enhancing your property's curb appeal. Moreover, black panels tend to hide dirt and grime better than lighter colors, making maintenance easier.

White Aluminum Fence Panels

On the other hand, white aluminum fence panels offer a clean, fresh look that complements coastal and cottage-style homes. White panels can brighten up your outdoor space, providing a crisp backdrop that highlights colorful flowers and shrubs. However, they may require more frequent cleaning to maintain their pristine appearance.

Influencing Overall Property Aesthetics

The choice between black and white, or any other color, should align with your overall design vision. Consider how the fence color will interact with your home's exterior, landscaping, and neighborhood aesthetic. Additionally, some homeowners associations (HOAs) may have specific guidelines regarding fence colors, so it's wise to verify any restrictions before making a decision.

For those seeking specialized color treatments, Sunmay Aluminum offers an extensive range of anodized finishes, allowing you to customize your fence to perfectly match your style. Their advanced techniques ensure vibrant, long-lasting colors that enhance both the beauty and durability of your panels.

In conclusion, selecting the right color for your aluminum fence panels is a crucial step in enhancing your property's aesthetic appeal. By considering factors such as style, maintenance, and HOA regulations, you can choose a color that not only complements your home but also elevates its overall charm and value.

Understanding Wholesale and Commercial Purchases

For those considering large-scale fencing projects, purchasing aluminum fence panels wholesale can offer significant cost savings and logistical advantages. But what exactly does buying wholesale entail, and how does it differ from retail purchases? Let's explore the key considerations and benefits of wholesale aluminum fence panels.

Cost Savings and Bulk Orders

One of the primary advantages of opting for aluminum fence panels wholesale is the potential for reduced costs. Wholesale purchases typically involve buying in bulk, which allows suppliers to offer lower per-unit prices compared to retail. This can be particularly beneficial for contractors, developers, or homeowners with extensive fencing needs. By purchasing in larger quantities, you can effectively lower the overall project cost, making it a more economical choice for expansive properties or commercial developments.

Meeting Commercial Specifications

When purchasing wholesale aluminum fence panels, it's crucial to ensure that the products meet specific commercial specifications. This includes considerations such as panel thickness, height, and finish quality. Many suppliers offer customization options to cater to varying project requirements, from industrial-strength panels for high-security areas to decorative options for enhancing aesthetic appeal. Ensuring that the panels comply with local building codes and standards is essential to avoid potential legal issues and ensure the safety and durability of the installation.

Retail vs. Wholesale: A Comparative Overview

| Factor | Retail | Wholesale |

|---|---|---|

| Price Per Unit | Higher | Lower |

| Order Quantity | Small to moderate | Large (bulk) |

| Customization | Limited | Extensive |

| Lead Time | Shorter | Longer (due to production) |

| Support | Basic | Comprehensive (often includes design and installation advice) |

As illustrated, wholesale purchases offer distinct advantages in terms of cost and customization, but they may require longer lead times due to the production and delivery of larger orders. This makes planning and timing crucial when opting for wholesale purchases.

In conclusion, understanding the nuances of wholesale aluminum fence panels can help you make informed decisions that align with your project needs and budget constraints. By considering factors such as cost savings, commercial specifications, and the differences between retail and wholesale purchases, you can ensure a successful and cost-effective fencing project.

Evaluating Sources and Installation Factors

When embarking on the journey to enhance your property with aluminum fence panels, knowing where to find these panels and understanding the installation essentials is crucial. Whether you're searching for 'aluminum fence panels near me' or exploring options for 'aluminum fence panels for sale,' the process involves several key considerations to ensure a successful outcome.

Finding Aluminum Fence Panels for Sale

Start by exploring local home improvement stores and specialized fencing suppliers, which often stock a variety of aluminum fence panels. These outlets provide the advantage of seeing the panels in person, allowing you to assess their quality and finish. Additionally, they may offer installation services or recommendations for local contractors who can assist with the setup.

Online platforms are another excellent resource, offering a broader range of options and competitive pricing. Websites like Fencing Direct and Aluminum Fences Direct provide comprehensive catalogs that include various styles and sizes. Shopping online allows you to compare prices and read customer reviews, which can be invaluable in making an informed decision.

Installation Essentials

Once you've sourced your panels, the next step is understanding the installation process. Proper planning is key, starting with marking the post locations and checking for underground utilities to avoid costly damages. Use a string line to ensure straight alignment, and carefully measure the spacing of post holes, typically set 72.5 inches apart. For detailed guidance, refer to installation guides provided by suppliers or consult with professionals.

Installation involves securing each panel to the posts with self-tapping screws, ensuring that the posts are level and aligned with the ground slope. Concrete is used to anchor the posts, with adjustments made before the concrete sets to maintain a consistent appearance.

Technical Support and Custom Solutions

For those seeking tailored solutions or needing technical support, consider reaching out to specialized providers like Sunmay Aluminum. Their expertise in custom aluminum profiles and advanced surface treatments can enhance both the aesthetic and functional aspects of your fence. Sunmay’s commitment to quality and customer satisfaction makes them a reliable partner for your fencing needs.

In conclusion, finding the right aluminum fence panels and understanding the installation process can significantly impact the success of your project. By utilizing local and online resources and considering expert support from companies like Sunmay Aluminum, you can achieve a durable and visually appealing fencing solution that enhances your property’s value and security.

Adapting Metal Panel Variations to Unique Needs

When considering fencing options, aluminum metal fence panels stand out due to their adaptability and modern design capabilities. These panels are not only about providing a boundary but also about enhancing the aesthetic and functional aspects of your property. Let's explore how these variations can cater to specialized installation needs and creative applications.

Exploring Aluminum Metal Fence Panels

Aluminum metal fence panels offer a unique combination of durability and design flexibility. They are crafted to withstand harsh weather conditions while maintaining their structural integrity. This makes them an ideal choice for properties located in areas prone to extreme climates. The lightweight nature of aluminum allows for easy handling and installation, reducing labor costs and time.

Moreover, these panels can be customized to meet specific design preferences. Whether you prefer a sleek, modern look or a more traditional appearance, aluminum panels can be tailored with various finishes and styles. Options such as powder coating provide a range of colors and textures, allowing homeowners to match their fencing to their home's exterior or landscape design.

Specialized Installations with Aluminum Panel Fence

One of the significant advantages of aluminum panel fences is their versatility in meeting specialized installation requirements. For example, properties with uneven terrain or unique architectural features can benefit from the customizable nature of aluminum panels. These panels can be fabricated to accommodate slopes, curves, and varying heights, ensuring a seamless fit across diverse landscapes.

Additionally, aluminum panels are suitable for both residential and commercial applications. In residential settings, they can be used to create private garden enclosures or secure pool areas, adhering to safety regulations. In commercial environments, aluminum panels can define property lines or enhance the security of industrial sites without compromising on style.

Creative Applications and Modern Fabrications

Modern fabrication techniques have expanded the possibilities for aluminum fencing, allowing for creative applications that go beyond traditional uses. For instance, decorative elements such as laser-cut designs or integrated lighting can transform a standard fence into a work of art, adding value and appeal to any property.

Furthermore, the integration of technology into aluminum fencing solutions is becoming increasingly popular. Features like automated gates and smart security systems can be seamlessly incorporated, offering convenience and enhanced security for property owners.

In conclusion, aluminum metal fence panels provide a versatile and innovative solution for those looking to enhance their property's boundary with style and functionality. By leveraging modern fabrication techniques and embracing creative designs, homeowners and businesses alike can achieve a fencing solution that meets their unique needs and elevates their property's overall appeal.

Preparing for Future Upgrades and Maintenance

When investing in residential aluminum fence panels, it's crucial to consider not only the immediate benefits but also future needs and maintenance to ensure longevity and sustained property value. Planning for potential expansions or reconfigurations can save time and resources down the line, while a regular maintenance routine will keep your fence looking pristine.

Planning for Future Expansion

As your property needs evolve, you might find the need to expand or modify your existing fence layout. Whether it's accommodating a new garden area or enhancing security features, aluminum fence panels offer flexibility for such changes. Their modular design allows for easy adjustments, and sections can be added or removed without significant effort. Before installation, consider consulting with a fencing expert to map out potential future expansions, ensuring that your initial setup can accommodate these changes seamlessly.

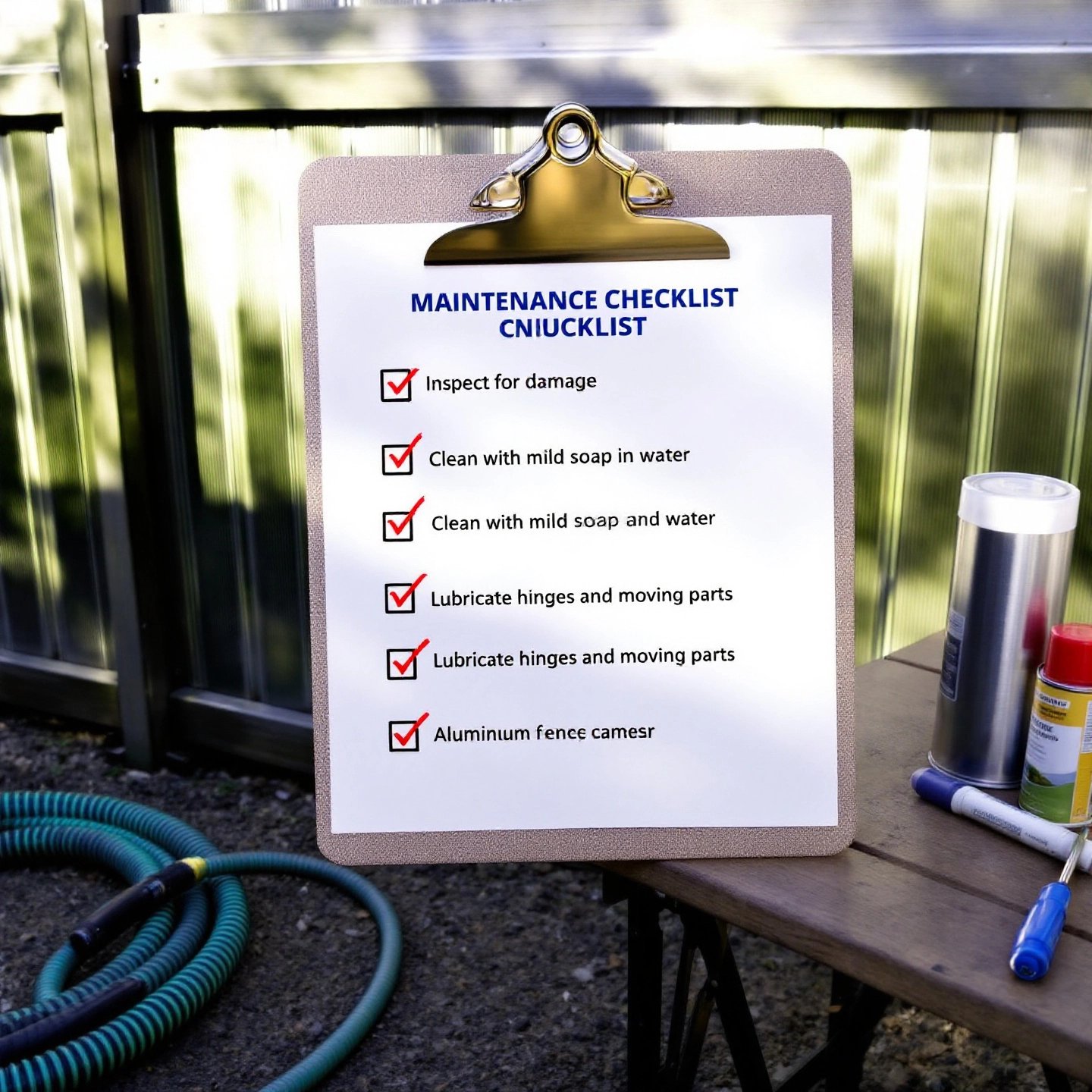

Maintenance Checklist for Longevity

Despite their low-maintenance reputation, aluminum fences benefit from routine care to maintain their appearance and structural integrity. Here’s a simple checklist to guide you:

- Regular Cleaning: Use mild soapy water to clean the panels, especially if you live in areas with high dust or pollution levels. Rinse thoroughly to avoid residue buildup.

- Inspect for Damage: Periodically check for loose screws or fasteners and tighten them as necessary. Look for any signs of wear or damage, particularly after severe weather conditions.

- Lubricate Moving Parts: Hinges and gate latches should be oiled regularly to ensure smooth operation and prevent rust.

- Check for Vegetation: Keep the area around the fence free from overgrown plants or debris that could cause damage or obstruct maintenance tasks.

- Address Oxidation: If you notice any chalky residue due to oxidation, gently clean the area and consider applying a protective wax to restore the shine.

By adhering to this maintenance routine, you can significantly prolong the lifespan of your aluminum fence, keeping it as a valuable asset to your property.

Value of Proactive Maintenance

Proactive maintenance not only enhances the visual appeal of your fence but also prevents minor issues from escalating into costly repairs. A well-maintained fence contributes to your property’s curb appeal and can be a selling point if you decide to move. Additionally, maintaining your fence helps in complying with local regulations and HOA standards, avoiding potential fines or mandatory repairs.

In summary, planning for future upgrades and adhering to a consistent maintenance schedule are essential steps in maximizing the benefits of residential aluminum fence panels. By doing so, you ensure that your fence remains a durable, attractive, and valuable feature of your property for years to come.

Conclusion

Throughout our exploration of aluminum fence panels, it’s evident why they have become a preferred choice for homeowners and businesses alike. Their durability, aesthetic versatility, and ease of maintenance make them an exceptional investment for enhancing both security and curb appeal. Unlike other materials, aluminum stands strong against the elements, offering a rust-free and long-lasting solution that requires minimal upkeep.

From the array of styles and dimensions available to the options for privacy and ornamental enhancements, aluminum fence panels cater to diverse needs and preferences. Whether you’re looking to define property boundaries, enhance privacy, or simply add a decorative element to your landscape, these panels provide the flexibility and elegance required to achieve your goals.

Moreover, the choice of color can significantly influence the overall look of your property, with popular options like black and white offering timeless appeal. For those seeking unique finishes, Sunmay Aluminum provides specialized treatments, ensuring your fence not only complements your home but also stands out with vibrant and enduring colors.

As you consider your fencing requirements, it’s crucial to evaluate factors such as local regulations, potential future expansions, and maintenance needs. By planning ahead and selecting quality materials, you can ensure a successful installation that enhances your property’s value and functionality.

In conclusion, aluminum fence panels offer a perfect blend of style, durability, and practicality. For those ready to make an informed choice, professional suppliers like Sunmay Aluminum are equipped to provide expert guidance and high-quality solutions tailored to your specific needs. Embrace the benefits of aluminum fencing and elevate your property’s appeal and security today.

Frequently Asked Questions about Aluminum Fence Panels

1. Is an aluminum fence cheaper than wood?

While aluminum fences have a higher upfront cost than wood, they offer greater durability and lower maintenance costs over time, making them cost-effective in the long run.

2. How much does 200 feet of aluminum fence cost installed?

The cost for installing 200 feet of aluminum fence can range from $5,000 to $15,000, depending on the style and specific installation requirements.

3. Which is cheaper, vinyl or aluminum fence?

Vinyl fences are generally cheaper upfront than aluminum. However, aluminum offers better durability and lower maintenance, making it a preferred choice for many.

4. What are the benefits of aluminum fence panels?

Aluminum fence panels are corrosion-resistant, lightweight, and easy to install. They offer aesthetic versatility and require minimal maintenance.

5. How do I choose the right aluminum fence panel for my property?

Consider your property's size, security needs, and local regulations. Choose a style that complements your home's architecture and meets your privacy requirements.